Various industries rely on switching power supplies for its compact design because it is capable of achieving efficient power conversion. In order to enhance system reliability and business performance, having automatic switching power supplies has become a standard, especially in the automation industry. In this article, we delve into the reasons why industrial automation companies continuously integrate switching power supplies into their systems by examining its key features and benefits.

The Basics of Switching Power Supply

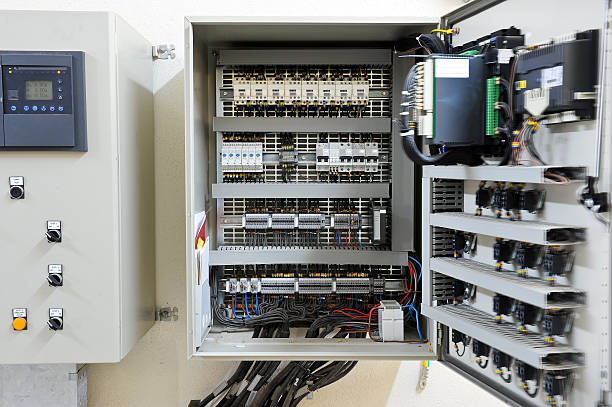

Switching power supplies differ from traditional linear power supplies in the manner in which they dissipate energy. Rather than converting excess energy into heat, switching power supplies efficiently convert electrical energy from one level to another using a high frequency switching regulator. This unique feature allows them to prolong the life of their components by remaining off for extended periods of time, greatly reducing their energy consumption. Switching power supplies are typically incorporated within systems that have an industrial grade level of automation, telecommunications, and even consumer electronics. By utilizing a SPS, the need for additional components in modern electronics such as desktop computers are virtually eliminated. Switching power supplies distribute power in a more affordable and accessible formfactor compared to traditional systems. Another benefit lies in that it can endure harsh environmental conditions without failure. The small size, reduced cooling system demand, and minimal heat generation of the SPS form a perfect fit for industrial automation firms. These attributes significantly reduce operational expenses while still efficiently managing space.

Most Important Aspects of Switching Power Supplies

Switching power supplies have many distinct characteristics that make them appealing for industrial automation companies. High efficiency in power consumption is one of their most important features. Switching power supplies, for example, which can change among various power levels tips the scale towards efficiency compared to linear power supplies which are much less efficient. With these supplies, the operational expenses are lowered, and heat generation is mitigated. In addition, power switching supplies are usually more compact in size than their linear counterparts enabling industrial automation companies to use them in confined spaces and improve the overall system design. Due to the nature of industrial environments with voltage changes, these companies are able to change their equipment, and or, devices that are adaptable or are flexible to a range of input voltages. The ability to change or adapt makes it suitable for different industrial sectors from manufacturing all the way to energy distribution since a vast range is opened up for devices that require different voltages. Switching power supplies have underlined features that also enable the equipment to provide built-in protection features like over current or over voltage protection so that the equipment is safe from potential risks. In addition, because of the high-frequency operational switching of these power supplies, minimal electromagnetic interference is produced which makes these supplies ideal for highly sensitive industrial automation systems where signal fidelity is important.

Advantages for Industrial Automation Companies

The application of these switching power supplies entails a range of benefits for the industrial automation companies. One cost is reduced, which is a major factor. The enhanced efficiency of switching power supplies reduces energy consumption, resulting in a lower electricity bill. Furthermore, reduced servicing needs and a longer lifespan help further decrease operational expenses. Switching power supplies also enhance reliability. With their advanced performance, equipment powered by these power supplies is guaranteed to function properly without unexpected interruptions. Losing equipment uptime is always expensive, but in industrial automation where every minute counts, a greater risk of power outages severely lowers system efficiencies. Their compact design and wide input voltage range permits greater freedom in system designs for industrial automation companies. These power supplies can also be incorporated into already existing automation setups, whether they be in robotics, conveyor systems or any other pieces of automated equipment. Improved safety is another notable advantage. Switching power supplies possess modern safety functions to protect against overcurrent, overvoltage, and overheating. Such features are crucial in industrial environments when equipment is prone to an electrical onslaught to avert danger to both the machinery and its operators.

In addition, numerous switching power supply units comply with stringent international safety certifications, providing industrial automation companies that have to meet strict regulatory compliances with an extra peace of mind.

The Role of Switching Power Supplies in Industrial Automation

The Function of Consistent Power Supply in Control Automation Systems Switching power supplies serve a key purpose by ensuring that the conversion of Power from one form to another is both reliable and constant, an essential facet that switching power supplies are very useful at. More energy-efficient and reliable power conversion is critical in the modern world of industrial automation. The importance of switching power supply engineering design to modern industrial automation companies is paramount which is seen through higher productivity and lower energy spending. These power supplies make it possible to get greater control over energy distribution within automation systems, increasing effectiveness while decreasing energy waste, which makes sure that the system as a whole consumes the correct amount of energy, and not anything excess. Along with the automation systems, which are developing more and more, switching power supplies offer a solution to increased power demand without taking up much valuable space. They allow automation industries to advance with technology and still ensure that their power layout system is flexible and expandable. Their capacity to service so many devices, machines, and sensors makes them even more important in industrial settings. With switching power supply technology development and deployment, power systems become more effective as newer generations of power load controlling automation devices and systems set the bar even higher with regards to EMC, power density, energy efficiency, and overall adaptability.

Why Choose Switching Power Supplies?

For industrial automation companies, the advantages within switching power supplies offer unparalleled savings and system performance. As industries invest more into automation, power conversion and solutions become fundamentally essential. Integrating switching power supplies saves a company’s money while improving system reliability and energy efficiency, therefore ensuring sustainable success in the market. Switching power supplies are more effective than older technologies as they are able to integrate with modern control systems seamlessly, increasing efficiency and reducing power losses. Hence, adopting switch power suppliers serves industrial automation companies greatly. From increased energy efficiency, reduced system footprint, or promised long term reliability, switching power suppliers is a technology that policymakers in any automation systems should consider. In adopting these power conversion efficiencies, companies do not sImply optimize their operations but rather work towards a more sustainable and profitable industrial ecosystem.