It is impossible to overestimate the significance of maintaining exact temperature control in many sectors. Whether it’s for preserving perishable goods, conducting sensitive experiments, or ensuring that high-value equipment operates within specific conditions, the need for consistent, reliable temperature regulation is paramount. One of the most effective ways to achieve this level of precision is through the use of controlled environment panels.

The purpose of controlled environment panels, sometimes referred to as temperature control panels or HVAC panels, is to maintain and manage particular environmental parameters, like airflow, humidity, and temperature, inside a designated area. These panels are particularly crucial in industries such as pharmaceuticals, food production, electronics manufacturing, and research laboratories, where even the slightest fluctuation in temperature can have detrimental effects.

Precision In Temperature Control

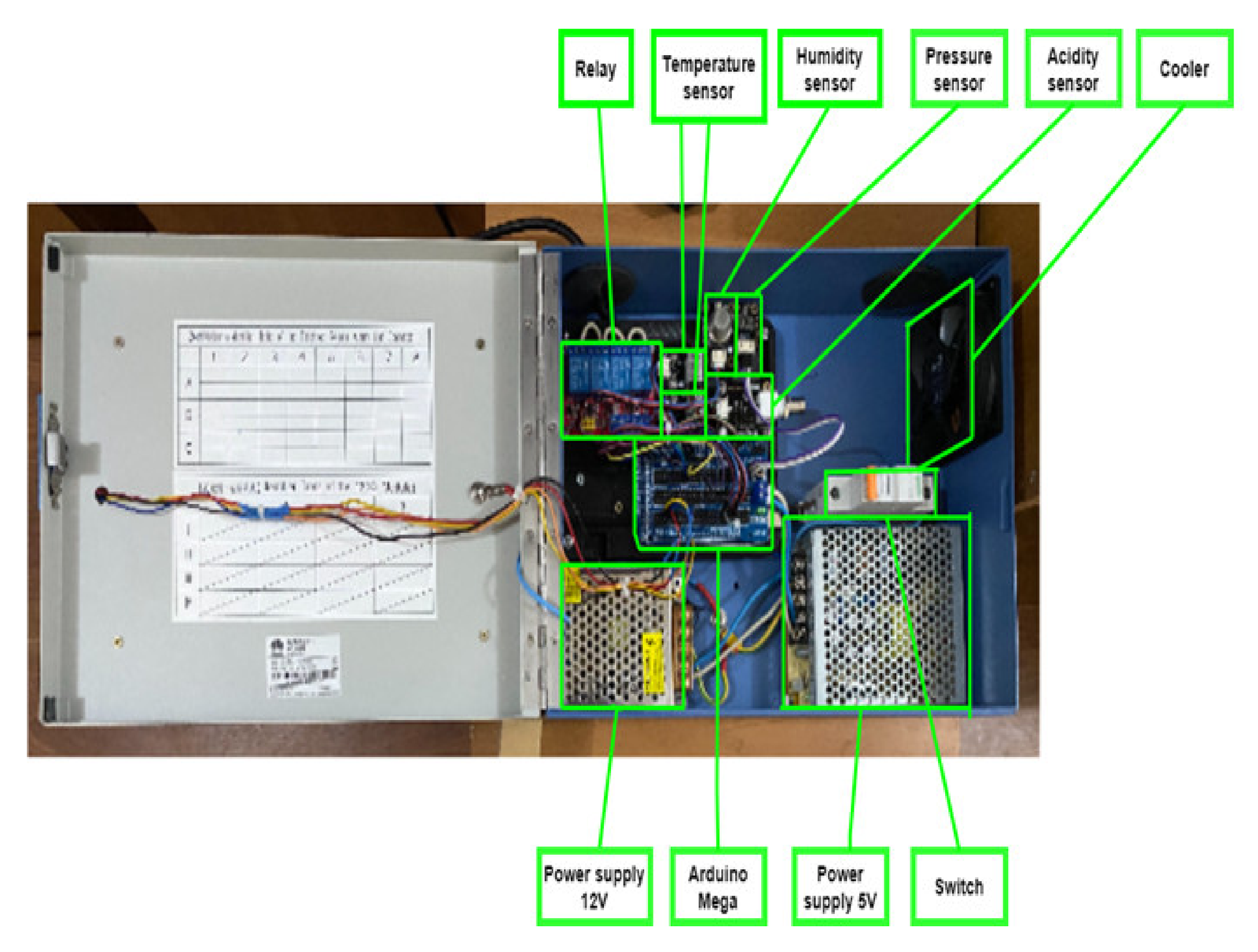

The capacity of controlled environment panels to give extremely precise and reliable temperature control is at their heart. The panels are integrated with advanced sensors, controllers, and actuators that work in unison to maintain the desired temperature with minimal deviation. In order to maintain the temperature within the specified setpoint, these systems continuously monitor and modify the surrounding environment.

For instance, in pharmaceutical manufacturing, the storage of drugs often requires very strict temperature ranges to maintain efficacy and safety. Any variation, even by a fraction of a degree, could render a batch of medication unusable or unsafe for consumption. Pharmaceutical firms can meet regulatory criteria and guarantee product quality by storing their products under ideal circumstances with controlled environment panels.

Similarly, in the food industry, controlled temperature panels help maintain the proper storage and transportation of perishable goods. Food goods must be kept at the proper temperature to avoid bacterial growth, spoiling, and other issues that could jeopardise their safety and quality. Whether it’s in a refrigerated warehouse, a cold chain transport system, or a retail display unit, these panels ensure that food items are kept at the correct temperature until they reach the consumer.

Advanced Technology For Enhanced Control

What sets controlled environment panels apart is the sophisticated technology embedded within them. These panels typically include digital controllers that can be easily programmed to maintain precise temperature settings. Some systems even feature Wi-Fi connectivity, allowing operators to monitor and adjust settings remotely, providing a high level of convenience and responsiveness.

Furthermore, certain contemporary systems provide predictive maintenance and optimisation through the integration of machine learning and artificial intelligence (AI). These technologies analyse historical data and environmental variables to anticipate changes and make adjustments before a temperature shift occurs, further enhancing the precision of the system.

Flexibility And Customisation

Another key benefit of metal insulated panels is their flexibility and customisation options. Industries with varying needs can tailor the panels to suit specific requirements. For example, some environments may require rapid cooling or heating, while others may need a more gradual temperature change. The ability to fine-tune the system allows businesses to create ideal conditions for their unique processes.

Additionally, controlled environment panels can be adapted to work with a range of different cooling and heating mechanisms, including air conditioning, refrigeration, and heating units. This adaptability makes them suitable for a wide array of applications, from the highly sensitive requirements of research laboratories to the robust needs of industrial manufacturing plants.

Energy Efficiency And Cost Savings

An often-overlooked benefit of controlled environment panels is their ability to reduce energy consumption. By maintaining a consistent temperature, the system reduces the need for constant adjustments, which can lead to energy waste. Many modern panels are designed with energy efficiency in mind, utilising advanced insulation, variable-speed motors, and energy-saving modes to minimise power usage.

These energy-saving measures have the potential to result in substantial cost savings over time, particularly for companies that depend on extensive temperature control systems. The combination of precision and energy efficiency not only ensures optimal conditions but also provides financial benefits, making controlled environment panels an excellent investment for businesses in temperature-sensitive industries. Sip panel manufacturers play a crucial role in producing high-quality panels that contribute to maintaining precise temperature control, ensuring optimal conditions for various industries.

Conclusion

Controlled environment panels are indispensable tools for ensuring precision in temperature control across a variety of industries. Their advanced technology, flexibility, and energy-efficient features allow businesses to maintain optimal conditions for everything from pharmaceuticals to food products. These panels are essential for guaranteeing the safety and quality of goods and procedures that rely on precise environmental conditions because of their real-time response to changes and, in some cases, their predictive capabilities. As industries continue to demand more from their temperature control systems, controlled environment panels will remain a key solution in achieving the highest standards of precision.

Keep an eye for more latest news & updates on Discover Craze!