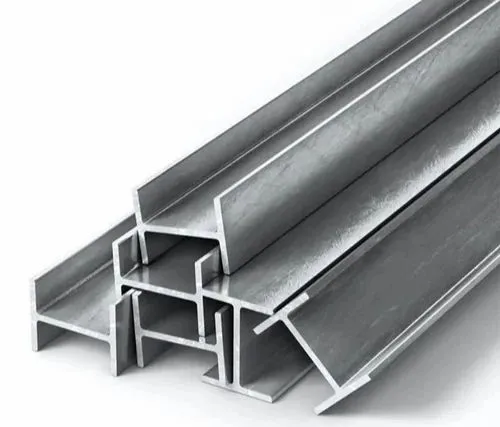

When choosing structural steel elements for a project, the proper type of beam or support must be selected to guarantee durability, stability, and cost-effectiveness. Channel steel and I-beams are two of the most popular structural steel forms, each with specific advantages and uses. Knowing how they differ will enable you to make a sound decision for your building or industrial project.

What is Channel Steel?

Channel steel, or C-channel or U-channel, is a cross-section that takes the shape of a “C” or “U”. It is a good support and reinforcement with a relatively light design. Channel steel is used in framing, structural reinforcements, and mechanical uses.

Types of Channel Steel

- Hot-Rolled Channel Steel – Manufactured at high temperatures, offering high strength and durability for heavy structural applications.

- Cold-Formed Channel Steel – Produced at lower temperatures, providing precise dimensions and smoother finishes, making it suitable for lighter applications.

- Galvanized Channel Steel – Coated with zinc for improved corrosion resistance, often used in outdoor or marine environments.

- Stainless Steel Channel – Highly resistant to rust and corrosion, suitable for chemical, food, and medical industries.

Common Applications of Channel Steel

- Structural support in buildings and bridges

- Frames for vehicles, trailers, and machinery

- Scaffolding and shelving units

- Construction of walkways and platforms

- Roof and wall framing in lightweight structures

What is an I-Beam?

An I-beam also known as an H-beam or a wide flange beam, has a cross-section that resembles the letter “I.” It has a middle web and two horizontal flanges, which makes it extremely efficient for load-carrying. I-beams are highly prevalent in construction, heavy equipment, and industrial buildings.

Types of I-Beams

- Standard I-Beam (S-Beam) – Features tapered flanges that provide strength while reducing weight, making it suitable for structural applications.

- Wide Flange Beam (W-Beam) – Has wider flanges for better weight distribution, making it ideal for heavy-duty structures.

- H-Beam – A heavier and wider version of the I-beam, often used in large-scale construction projects.

Common Applications of I-Beams

- Skyscraper and bridge construction

- Support beams for industrial buildings and warehouses

- Structural columns in high-rise buildings

- Railway tracks and heavy equipment frameworks

- Offshore platforms and shipbuilding structures

Key Differences Between Channel Steel and I-Beam

| Feature | Channel Steel (C-Channel) | I-Beam (H-Beam) |

| Shape | C or U-shaped | I-shaped with a central web and two flanges |

| Weight | Lighter, easier to handle | Heavier, stronger load capacity |

| Load-Bearing Capacity | Suitable for moderate loads | Excellent for heavy loads |

| Structural Stability | Less resistant to bending under heavy loads | Distributes weight evenly for maximum stability |

| Ease of Installation | Easier to cut, install, and modify | Requires more structural support and precision installation |

| Cost | More affordable for smaller projects | Higher cost due to additional material and load-bearing capacity |

| Common Uses | Framing, reinforcements, vehicle chassis | Large buildings, bridges, and industrial applications |

| Corrosion Resistance | Available in galvanized and stainless steel options | Requires protective coatings for rust resistance |

Pros and Cons of Channel Steel vs. I-Beam

Advantages of Channel Steel

- Lightweight and easy to handle, making it suitable for small to medium-scale projects.

- More affordable compared to I-beams, reducing overall construction costs.

- Versatile applications, including framing, shelving, and scaffolding.

- Can be reinforced with additional supports for improved load-bearing capacity.

Disadvantages of Channel Steel

- Not suitable for extremely heavy loads, as it may bend under excessive pressure.

- Less stability compared to I-beams, requiring additional reinforcement for large structures.

Advantages of I-Beams

- Superior load-bearing capacity, making them ideal for large-scale construction.

- Even weight distribution reduces stress on structural components.

- High durability and resistance to deformation under heavy loads.

Disadvantages of I-Beams

- Higher cost due to increased material usage and weight.

- Requires specialized equipment and expertise for cutting and installation.

- Heavier weight makes transportation and handling more challenging.

When to Choose Channel Steel vs. I-Beam

Choose Channel Steel If:

- The project involves moderate-weight loads, such as framing, support structures, or shelving.

- Cost is a significant factor, and a more affordable solution is required.

- Ease of installation and modifications are essential for the project.

- Corrosion resistance is necessary, such as in outdoor applications where galvanized or stainless steel is beneficial.

Choose I-Beam If:

- The project requires support for heavy loads, such as in large buildings or industrial applications.

- Structural stability is a top priority, ensuring even weight distribution.

- The design involves spanning long distances without sagging or deformation.

- A long-term, high-durability solution is needed, justifying the higher cost.

Cost Comparison: Channel Steel vs. I-Beam

Factors Affecting Cost

- Material Type – Stainless steel and galvanized versions are more expensive than carbon steel.

- Size and Thickness – Larger and thicker beams cost more due to increased material usage.

- Manufacturing Process – Cold-formed steel is typically cheaper than hot-rolled steel.

- Supplier and Location – Prices vary depending on supplier, shipping costs, and market conditions.

General Pricing Trends

- Channel steel is generally more affordable than I-beams due to its lower weight and material usage.

- I-beams have a higher initial cost but offer long-term savings due to their durability and stability.

- Buying in bulk or directly from manufacturers can significantly reduce costs for both options.

Final Verdict: Which One is Best for Your Project?

The choice between Cheap channel steel and I-beams would be based on the load requirement, cost, and structural requirements of your project.

If the project is to accommodate light to moderate loads, needs inexpensive and simple-to-install framing, or necessitates corrosion resistance, channel steel is the best option.

For huge buildings, bridges, and high-load applications where structural strength and stability are of utmost importance, I-beams are the best choice.

It’s always best to talk to a structural engineer to decide the optimum steel component for your particular application, with a focus on safety and long-term function.

To buy any kind of metal Midwest Steel is the Best Choice.