A pressure switch is an essential device in numerous industrial and commercial systems, playing a pivotal role in 0533205 Pressure Switch maintaining the operational safety and functionality of equipment. These devices are designed to activate or deactivate an electrical circuit based on the pressure within a system. When the system pressure reaches a preset value, the pressure switch either opens or closes a contact to control other machinery or devices. This action helps maintain the system pressure within a predefined range, preventing damage to the system caused by either excessive or insufficient pressure. Essentially, the pressure switch acts as a gatekeeper, ensuring that the system 0533205 Pressure Switch operates within its optimal pressure limits.

In technical terms, pressure switches operate using a sensing element such as a diaphragm, piston, or Bourdon tube that responds to the change in pressure. The movement of these sensing elements actuates a switch mechanism, either opening or closing electrical contacts. The 0533205 Pressure Switch is one such example, offering precision and durability for applications across multiple industries. Given the wide variety of systems that rely on proper pressure management, the role of pressure switches like the 0533205 Pressure Switch cannot be understated. From air compressors to hydraulic systems, pressure switches 0533205 Pressure Switch are critical to the seamless operation of many machines.

The 0533205 Pressure Switch: Overview

The 0533205 Pressure Switch is an advanced version of traditional pressure switches, offering enhanced reliability, sensitivity, and longevity. This specific model has garnered attention due to its excellent performance in demanding environments, making it a top choice for industries where precision and durability are critical. It is engineered to handle a variety of pressures with minimal fluctuation, maintaining consistent performance across a range of temperatures and environments. Unlike generic pressure switches, the 0533205 model is known for its ability to operate flawlessly even under extreme conditions, providing the peace of mind that systems are always functioning within their safe pressure parameters.

In terms of its construction, the 0533205 Pressure Switch is crafted using high-quality materials that are resistant to wear and corrosion. This makes it suitable for industries that expose components to harsh chemicals, extreme temperatures, and high humidity. Its wide range of application compatibility makes it invaluable in sectors like manufacturing, HVAC, water treatment, and automotive. As with most modern pressure switches, the 0533205 includes features like adjustable set points, robust contacts, and a durable housing, ensuring optimal performance and minimal maintenance. These characteristics help businesses improve safety standards, reduce operational downtime, and enhance system efficiency.

How Does the 0533205 Pressure Switch Work?

The 0533205 Pressure Switch operates by responding to pressure changes within a system. The internal mechanism typically includes a pressure-sensing element like a diaphragm, which reacts to pressure fluctuations by moving. This movement is then translated into an electrical signal that either opens or closes the switch’s contacts. These electrical contacts control external devices such as pumps, valves, or alarms that regulate or respond to changes in pressure. This allows systems to automatically adjust based on predefined pressure thresholds, preventing them from operating outside their designed parameters.

For example, in an HVAC system, the might be set to activate a compressor if the pressure falls below a specific value or deactivate it when the pressure exceeds a particular limit. The switch is calibrated so that when the system reaches either of these conditions, the switch will trigger an action to prevent further pressure changes. In this way, the 0533205 Pressure Switch helps maintain system balance, reducing the risk of system failure, damage, or inefficiency. Furthermore, by using such a switch, operators can improve system control, ensuring that machinery is only working when necessary, thus conserving energy and reducing wear and tear.

Applications of the 0533205 Pressure Switch

The 0533205 Pressure Switch is a versatile component widely used in various sectors due to its robustness and ability to monitor pressure effectively across multiple media types such as air, gases, liquids, and more. Below are some notable applications where the 0533205 Pressure Switch excels:

1. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, pressure regulation is essential for optimal performance. The 0533205 Pressure Switch helps monitor the refrigerant pressures, ensuring that the system operates within safe ranges. If the pressure deviates from preset values, the switch triggers an action to correct the issue, such as turning off a compressor or starting a backup system. This is vital in maintaining efficient cooling and heating, as excessive pressure can lead to system breakdowns, energy inefficiency, or even hazardous conditions. By using the

2. Automotive Industry

In the automotive industry, pressure switches like the 0533205 are used to ensure the proper functioning of engine systems, including oil pressure monitoring, fuel system pressure, and coolant system pressure. A drop in oil pressure, for example, is an indicator of potential engine trouble, which can be immediately flagged by the 0533205 Pressure Switch, triggering an alarm or warning light. These switches provide real-time data that helps drivers or mechanics detect issues early, avoiding costly repairs or engine damage. Their ability to operate reliably in harsh automotive environments, where high temperatures and vibrations are prevalent, makes them ideal for the task.

3. Water Treatment Systems

Water treatment plants depend on various sensors to ensure that pressure within pumps and filtration systems stays within operational thresholds. The s commonly deployed to monitor pressures in reverse osmosis systems, filtration units, and pumping stations. If the pressure drops too low, it can signify clogged filters or pump malfunctions, while excessive pressure can lead to system ruptures. The 0 ensures that the water treatment system runs smoothly by automatically shutting down pumps or activating alarms when necessary. This proactive approach improves safety, efficiency, and reliability within these critical systems.

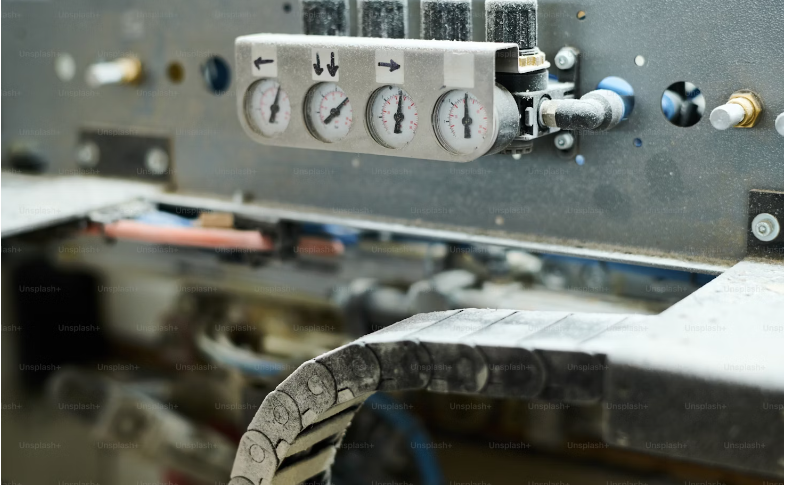

4. Industrial Machinery

Industrial machinery often involves complex hydraulic and pneumatic systems that require precise pressure monitoring. In these settings, the 0533205 Pressure Switch is utilized to prevent overpressure situations, which can cause catastrophic equipment damage. For instance, in a hydraulic press, too much pressure can result in costly repairs, while too little pressure may compromise performance. The 0533205 Pressure Switch ensures that hydraulic and pneumatic systems are constantly operating within safe and efficient pressure ranges. This provides protection against operational failures, extends the lifespan of expensive equipment, and enhances overall productivity.

5. Compressors and Pumps

Compressors and pumps are critical components in many industrial applications, including refrigeration, oil and gas, and water treatment. Maintaining stable pressure is vital to the efficiency and longevity of these systems. The monitors the pressure levels in compressors and pumps, ensuring that they operate within the optimal range. If the pressure falls outside the preset limits, the switch can automatically turn off the compressor or adjust the system to prevent damage. This reduces downtime, energy consumption, and costly maintenance while ensuring continuous system operation.

Benefits of Using the 0533205 Pressure Switch

The 0533205 Pressure Switch offers numerous advantages that make it a highly sought-after component across various industries. Below are some of the key benefits that highlight why this model is chosen over other alternatives:

1. Enhanced Safety

The primary function of the 0533205 Pressure Switch is to ensure that systems stay within safe operational limits. By continuously monitoring pressure, it helps prevent overpressure or underpressure scenarios that could lead to dangerous situations like explosions, leaks, or equipment failure. In industrial settings, where pressure vessels, boilers, and pumps are common, the consequences of improper pressure regulation can be severe. The 0533205 Pressure Switch acts as a safety mechanism to prevent these risks, ensuring the safe and reliable operation of systems.

2. Improved System Efficiency

When systems operate at their optimal pressure range, they tend to function more efficiently, consuming less energy and reducing unnecessary wear. The 0533205 Pressure Switch provides constant pressure monitoring, which helps maintain the balance required for maximum efficiency. By ensuring that components such as compressors, pumps, and valves function within their ideal pressure parameters, the switch reduces energy waste, minimizes system strain, and lowers operating costs. This efficiency also extends to the longevity of equipment, further contributing to long-term cost savings.

3. Cost Savings

One of the key reasons why businesses invest in pressure switches like the is the long-term cost savings. By preventing system failures, reducing downtime, and extending the lifespan of expensive equipment, this pressure switch helps businesses avoid costly repairs or replacements. Additionally, maintaining optimal pressure within systems minimizes energy consumption, reducing utility bills. In industries where equipment is a major financial investment, such as manufacturing, HVAC, and automotive sectors, this can lead to significant savings.

4. Ease of Maintenance

The 0533205 Pressure Switch is designed for durability and minimal maintenance. Its sturdy construction ensures that it can withstand harsh environments, reducing the likelihood of wear and tear. The switch is also designed for easy calibration and adjustment, allowing technicians to fine-tune the settings with minimal downtime. This ease of maintenance is an important consideration for industries that operate on tight schedules and need to ensure that systems are running smoothly with minimal interruptions.

Installation and Calibration of the 0533205 Pressure Switch

To ensure that the 0533205 Pressure Switch performs optimally, proper installation and calibration are essential. Below is a step-by-step guide to assist with the installation and calibration of this switch:

1. Installation

The installation of the 0533205 Pressure Switch requires that the system be depressurized before any work begins. Safety precautions, such as turning off the power supply and isolating the system, should be taken to avoid accidents. Once the system is safe to work on, the pressure switch should be installed at a location where it can effectively monitor system pressure. The device should be positioned in line with the pressure source, ensuring that the sensing element is exposed to the correct pressure. Electrical connections should be made following the manufacturer’s guidelines to avoid any short circuits or operational failures.

2. Calibration

Calibration of the 0533205 Pressure Switch involves adjusting the set points to match the required pressure range for the system. A calibrated pressure source should be used to simulate varying pressure conditions. During this process, the technician should adjust the switch’s set points until the switch activates or deactivates as expected at the desired pressure levels. Calibration tools and procedures outlined in the product manual should be followed closely to ensure accuracy. This ensures that the switch responds correctly and that the system operates within its safe pressure limits.

Troubleshooting the 0533205 Pressure Switch

While the 0533205 Pressure Switch is highly reliable, some issues may arise due to external factors or system malfunctions. Common troubleshooting steps include:

- Electrical Issues: Check for loose or damaged wires, as these can affect the operation of the switch. Ensure all connections are secure.

- Set Point Calibration: Ensure that the set points are correctly adjusted to match the system’s required pressure range. If necessary, recalibrate the switch.

- Physical Damage: Inspect the switch for any visible damage or wear, such as cracks in the housing or a bent diaphragm. Replace if necessary.

- System Pressure Issues: Verify that the pressure within the system is within the expected range. Sometimes, pressure fluctuations outside the switch’s operating range can cause false readings or failure to trigger.

Conclusion

The 0533205 Pressure Switch is a vital component that ensures system efficiency, safety, and performance across numerous industries. With its precision, durability, and versatility, it stands as one of the best options for applications requiring reliable pressure monitoring. By understanding the switch’s functions, applications, benefits, and proper installation and maintenance procedures, users can significantly enhance the longevity and reliability of their systems.