Introduction

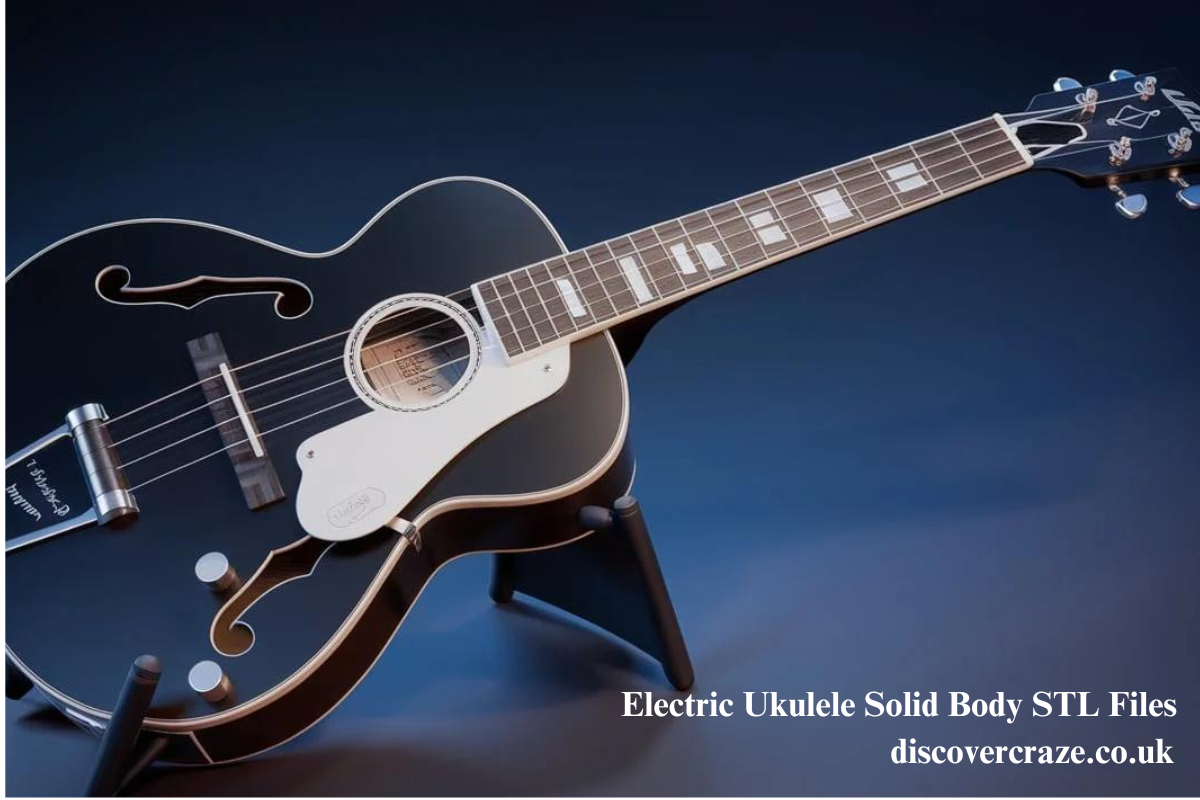

Electric Ukulele Solid Body STL Files, The ukulele is a beloved string instrument, known for its cheerful sound and portability. With the rise of modern music and technology, many musicians are now exploring the electric ukulele. This article will guide you through the process of designing and creating STL files for a solid body electric ukulele, making it accessible and enjoyable for both hobbyists and experienced builders.

Understanding the Electric Ukulele

What is an Electric Ukulele?

An electric ukulele amplifies sound through electronic pickups, similar to electric guitars. This allows for greater volume, effects integration, and versatility in music styles. Solid body electric ukuleles are constructed without a resonating chamber, resulting in a more focused sound and a unique aesthetic.

Why Design Your Own?

Creating your own electric ukulele offers several benefits:

Customization: Tailor the design to your personal style and preferences.

Learning Experience: Gain valuable skills in design, engineering, and electronics.

Creativity: Express your artistic vision in a tangible way.

Designing the Electric Ukulele

Step 1: Gather Inspiration

Before diving into design, explore existing models. Look at various shapes, sizes, and materials. Platforms like Pinterest, music stores, and online forums can provide a wealth of ideas. Pay attention to the aesthetics, ergonomics, and functionality of different designs.

Step 2: Define Your Specifications

Decide on key aspects of your electric ukulele:

Scale Length: Common ukulele sizes are soprano (21 inches), concert (23 inches), tenor (26 inches), and baritone (30 inches). Choose one that fits your playing style.

Body Shape: Consider a traditional shape or experiment with modern designs.

Materials: Solid body ukuleles are often made from wood or composite materials. Choose one that complements your sound preferences and aesthetics.

Electronics: Select pickups (single coil, humbucker) and other electronic components. Research how they influence tone and playability.

Step 3: Sketch Your Design

Once you have a clear vision, sketch your design. Use paper or digital drawing tools to create front and side views. Focus on proportions, contours, and unique elements like cutaways or contours for comfort.

Step 4: 3D Modeling

Choosing Software

To create STL files, you’ll need 3D modeling software. Popular options include:

Fusion 360: Great for precision modeling and engineering aspects.

Blender: Excellent for organic shapes and artistic designs.

Tinkercad: User-friendly and suitable for beginners.

Building the Model

Start with the Body: Create the main body shape based on your sketch. Consider thickness and contour for comfort and aesthetics.

Add the Neck: Design the neck, ensuring it fits snugly into the body. Decide on the fretboard material and layout.

Include Hardware Mounts: Model areas for pickups, bridges, and tuners. Precision in these areas is crucial for proper assembly.

Exporting to STL: Once satisfied with your design, export it as an STL file. Most software has a straightforward export function.

Step 5: Preparing for 3D Printing

Selecting a 3D Printer

Choose a 3D printer capable of handling the material you selected. Common options include:

FDM Printers: Great for budget-friendly printing; use PLA or ABS for solid bodies.

Resin Printers: Ideal for detailed parts, though typically more expensive.

Slicing the Model

Use slicing software (like Cura or PrusaSlicer) to convert your STL files into G-code. Adjust settings for layer height, infill, and supports, depending on your printer and material.

Step 6: Printing the Ukulele

Once your model is sliced, it’s time to print! Monitor the process to ensure everything is going smoothly. Printing can take several hours, depending on the size and complexity of the design.

Step 7: Assembly and Finishing

Post-Processing

After printing, you may need to sand the surfaces for a smooth finish. Consider painting or staining to enhance aesthetics. If your design includes intricate features, consider using a wood veneer or covering for a polished look.

Installing Electronics

Install your pickups, wiring, and any other electronic components. Follow wiring diagrams carefully to ensure proper functionality. If you’re unsure, consult online tutorials or reach out to a community for guidance.

Step 8: Set Up and Play

Once assembled, set up your electric ukulele. Adjust the action, intonation, and tuning to your preference. Finally, plug it in and enjoy playing!

Case Study: From Concept to Creation – Building an Electric Ukulele

Background:

Emily, an avid ukulele player and DIY enthusiast, wanted to create her own electric ukulele to enhance her performances. With limited experience in 3D modeling, she decided to document her journey.

Design Phase:

Emily began by researching various electric ukulele designs, noting features she liked. After sketching a unique body shape and defining her specifications, she selected a tenor scale length and opted for a comfortable contour.

3D Modeling:

Using Fusion 360, Emily modeled her design, paying close attention to the neck and pickup placements. After exporting her design as an STL file, she felt a sense of accomplishment.

Printing Process:

Emily chose an FDM printer and carefully set her slicer settings. The printing process took around eight hours. Post-printing, she sanded and painted the body, giving it a vibrant finish.

Assembly:

Installing the electronics was the most challenging part. Emily followed online tutorials to wire the pickups correctly. After some adjustments to the setup, she finally strummed her newly built electric ukulele.

Results:

Emily’s custom ukulele not only looked stunning but also produced a rich sound that suited her style. She gained confidence in her crafting skills and inspired others in her music community to explore instrument building.

FAQ

What materials are best for a solid body electric ukulele?

Common choices include hardwoods like maple and mahogany for durability and aesthetics, as well as composites for lightweight options.

Can I use any 3D printer for this project?

While most FDM printers will work, ensure your printer can handle the material you choose. Resin printers can also be used for finer details.

How do I select the right pickups?

The choice depends on your sound preference. Single coil pickups offer a bright tone, while humbuckers produce a warmer, fuller sound.

Is 3D modeling difficult for beginners?

It can be challenging, but software like Tinkercad is user-friendly for newcomers. There are plenty of online tutorials to help you get started.

How can I customize the sound of my electric ukulele?

Besides the pickups, consider experimenting with different strings, changing the electronics setup, or adding effects pedals to enhance your sound.

Conclusion

Designing and building a solid body electric ukulele from STL files is an exciting journey that combines creativity, engineering, and musicality. Whether you’re a seasoned builder or a newcomer, the process can be immensely rewarding. With patience and attention to detail, you’ll create a unique instrument that reflects your personal style and enhances your musical expression. So gather your materials, fire up your 3D printer, and embark on this creative adventure!